By: Tony Humble, Chairman & CEO, Soilcare.Earth

Most composts are viewed as nutrient sources, and the recommendations for applying them are based on the composts’ nitrogen and phosphorus content. In addition to composts’ role as nutrient sources, however, a growing body of research suggests that certain composts can provide soil microbial communities that bring many benefits for plants and soils. In these processes, fungi play an especially important role.

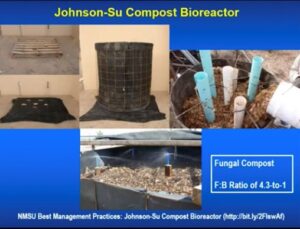

The compost produced in the Johnson-Su composting bioreactor provides nutrients and, more importantly, results in a microbially diverse and fungal-dominant soil microbiome that can be applied at concentrations as low as 1 lb per acre, a concentration at which it operates more as a microbial inoculation for soils, than as a soil amendment. “Plentiful fungi” appears to be a key indicator for soil quality in the compost produced in the Johnson-Su bioreactor.

Benefits of the Johnson-Su Composting Bioreactor

Most composting methodologies require building a pile and turning it at regular intervals. In contrast, when built and maintained correctly, the static pile Johnson-Su bioreactor never needs turning, never has smells, and does not attract flies. This reactor design allows the material to be composted aerobically, allowing complete biological breakdown of compost materials and resulting in a microbially diverse, fungal-dominant compost product. The compost end product has the consistency of clay when mature (you can squeeze the end-product between your fingers and it oozes out like clay).

The mature compost can be applied as an extract, mixed as a slurry to coat seeds that you intend to plant, or be applied directly as a soil amendment. The compost from Johnson-Su composting bioreactors improves seed germination rates when used to coat seeds, improves soil water infiltration and water retention by helping to increase soil carbon content, and increases plant health, plant growth rates, and crop production.

Build a low cost compost pile- no turning needed

Produces no odors or associated insects; and reduces nutrient volatilization and leaching. A “HIGH QUALITY” nutrient rich, high-microbial-biomass & biodiverse compost is the result.

How to Use Compost from a Johnson-Su Composting Bioreactor

After a composting period of 9 months to a year, the compost product from a Johnson-Su bioreactor can be used as it is, made into a slurry to coat seeds, or used to make an extract that can be sprayed on a field or into the furrow as you plant seeds.

Direct Application

Without any further treatment after the composting period, the compost product from the Johnson-Su bioreactor can be used as a growing media, spread onto soils at any desired rate, or used as a soil substitute. Mix in some native soil, about 1/3 by volume, to offer additional material from which the microbes can extract macro and micro-nutrients that are needed for plant growth.

Extracts

Compost product from a Johnson-Su bioreactor can also be used to create liquid extracts that contain a rich and diverse community of soil microbes, especially fungi. The compost extracts are especially useful for inoculating large areas with beneficial soil microbial communities.